Manage Inventory Like a Pro: Mastering inventory management is crucial for any business aiming for profitability and efficiency. This guide delves into the core principles, offering practical strategies and advanced techniques to optimize your inventory processes, from fundamental concepts like FIFO and LIFO to the implementation of cutting-edge technologies such as RFID and cloud-based solutions. We’ll explore how to forecast demand accurately, minimize waste, and build a high-performing inventory management team.

Through detailed explanations, practical examples, and insightful comparisons of different methods and systems, you’ll gain a comprehensive understanding of how to streamline your inventory operations, reduce costs, and ultimately boost your bottom line. Whether you manage a small business or a large enterprise, this guide provides the knowledge and tools to transform your inventory management from a challenge into a competitive advantage.

Understanding Inventory Management Fundamentals

Effective inventory management is crucial for any business, regardless of size or industry. Maintaining optimal inventory levels directly impacts profitability, customer satisfaction, and overall operational efficiency. Poor inventory management can lead to stockouts, lost sales, and excessive storage costs, while overstocking ties up capital and increases the risk of obsolescence or spoilage. Understanding the core principles and implementing appropriate methods are essential for success.

Core Principles of Effective Inventory Management

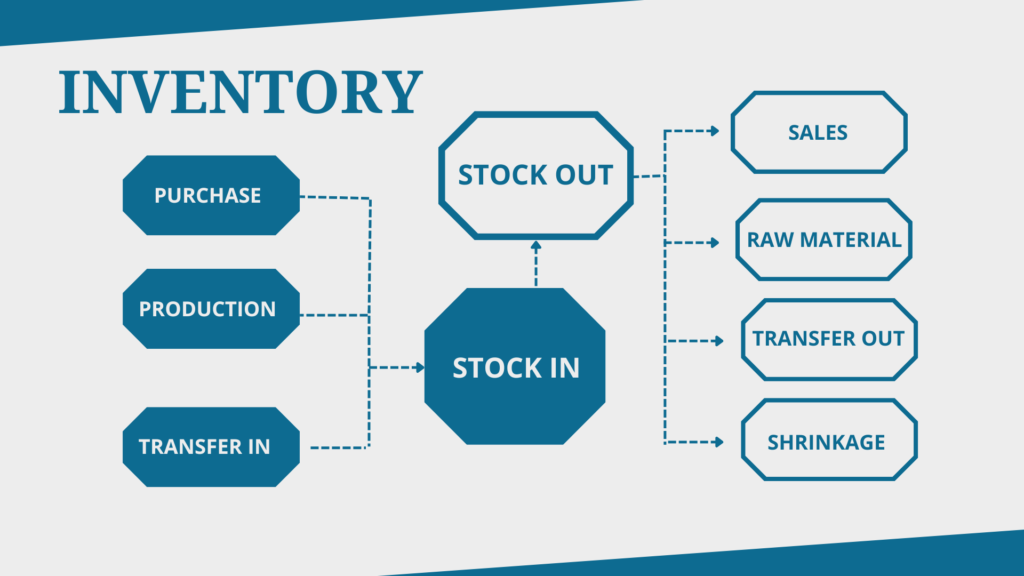

Effective Manage Inventory Like a Pro inventory management hinges on several key principles. Accurate record-keeping is paramount, ensuring that inventory data reflects reality. This involves meticulous tracking of incoming and outgoing goods, regularly updating stock levels, and promptly addressing discrepancies. Demand forecasting plays a vital role in predicting future needs, enabling businesses to procure and stock items accordingly. This minimizes the risk of shortages or surpluses. Efficient storage and handling practices are also essential, ensuring goods are protected from damage and easily accessible when needed. Finally, regular inventory audits provide a snapshot of the current state of inventory, identifying areas for improvement and preventing potential issues.

Inventory Management Methods

Several methods exist for managing inventory, each with its own advantages and disadvantages. Choosing the right method depends on the specific needs and characteristics of the business. The three most common methods are FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and the Weighted Average Cost method.

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| FIFO (First-In, First-Out) | Items are sold in the order they were received. The oldest inventory is sold first. | Reduces the risk of obsolescence or spoilage, provides a more accurate cost of goods sold (COGS) reflection of current market prices. | Can lead to higher COGS during periods of inflation, requires more meticulous tracking of inventory. |

| LIFO (Last-In, First-Out) | Items are sold in the reverse order they were received. The newest inventory is sold first. | Can result in lower taxable income during periods of inflation (though this is less common under current accounting standards), simplifies inventory valuation in some situations. | Can lead to an inaccurate reflection of COGS, increases the risk of obsolescence or spoilage of older inventory. |

| Weighted Average Cost | The average cost of all items in inventory is used to determine the cost of goods sold. | Simple to calculate and implement, smooths out price fluctuations. | May not accurately reflect the true cost of goods sold, particularly during periods of significant price changes. |

Conducting an Inventory Audit

A thorough inventory audit is a systematic process of verifying the accuracy of inventory records against physical inventory. This helps identify discrepancies, prevent losses, and improve overall inventory management.

- Planning and Preparation: Define the scope of the audit, determine the timeframe, assemble the necessary team and resources (counting sheets, scanners, etc.), and schedule the audit during a period of minimal disruption.

- Counting Inventory: Physically count all items in inventory, using a standardized counting method. Clearly label and identify each item, noting its quantity and condition.

- Reconciling Inventory Records: Compare the physical count results with the inventory records. Identify any discrepancies between the physical count and the recorded quantities.

- Investigating Discrepancies: Investigate the causes of any discrepancies found. This may involve checking purchase orders, sales records, and other relevant documents. Common causes include data entry errors, theft, damage, or obsolescence.

- Adjusting Inventory Records: Adjust the inventory records to reflect the actual physical count. Document all adjustments made and their reasons.

- Reporting and Analysis: Prepare a report summarizing the findings of the audit, including the total value of inventory, any discrepancies found, and their causes. Analyze the results to identify areas for improvement in inventory management processes.

Optimizing Inventory Levels

Effective Manage Inventory Like a Pro hinges on optimizing stock levels. This involves a delicate balancing act between minimizing carrying costs (the expenses associated with storing and maintaining inventory) and avoiding stockout costs (the losses incurred when demand exceeds supply). Successfully navigating this balance directly impacts profitability and overall business efficiency.

Carrying costs encompass storage fees, insurance, taxes, obsolescence, and the opportunity cost of capital tied up in inventory. Stockout costs, on the other hand, include lost sales, potential damage to customer relationships, expedited shipping fees to replenish stock, and the disruption of production processes. High inventory levels lead to increased carrying costs, while low levels risk stockouts and their associated expenses. The goal is to find the sweet spot that minimizes the total cost of inventory management.

The Impact of Carrying and Stockout Costs on Profitability

Minimizing the total cost, which is the sum of carrying and stockout costs, is crucial for maximizing profitability. Consider a retailer selling seasonal clothing. Holding excessive winter coats into the summer increases carrying costs (storage, potential for obsolescence). Conversely, running out of popular summer dresses during peak season leads to lost sales and dissatisfied customers (stockout costs). A well-designed inventory management system aims to prevent both scenarios. Analyzing historical sales data, understanding demand fluctuations, and using appropriate forecasting methods are essential in this process. For example, a detailed analysis might reveal that carrying costs for a particular item are $1 per unit per month, while a stockout costs $5 per unit due to lost sales and expedited shipping. This information is crucial for making informed decisions about inventory levels.

Forecasting Demand Using Historical Sales Data and Seasonal Trends, Manage Inventory Like a Pro

Accurate demand forecasting is the cornerstone of optimized inventory levels. This involves analyzing past sales data to identify trends and patterns, incorporating seasonal variations, and considering external factors like economic conditions or marketing campaigns. A simple approach might involve calculating a moving average of past sales figures to predict future demand. More sophisticated methods include exponential smoothing or time series analysis, which can account for trends and seasonality more effectively. For instance, a bicycle shop might analyze its sales data over the past five years, noting a significant peak in sales during spring and summer months. This seasonal trend informs their inventory planning, ensuring sufficient stock of bicycles during peak demand periods while avoiding overstocking during the off-season.

Calculating Optimal Reorder Points and Economic Order Quantities (EOQ)

Determining the optimal reorder point (ROP) and economic order quantity (EOQ) are critical steps in inventory optimization. The reorder point is the inventory level at which a new order should be placed to avoid stockouts, considering lead time (the time it takes for an order to be delivered) and demand during that period. The EOQ is the order quantity that minimizes the total inventory costs (ordering costs and carrying costs). The basic EOQ formula is:

EOQ = √[(2DS)/H]

Where:

* D = annual demand

* S = ordering cost per order

* H = holding cost per unit per year

For example, if a company has an annual demand of 10,000 units, an ordering cost of $100 per order, and a holding cost of $5 per unit per year, the EOQ would be:

EOQ = √[(2 * 10,000 * 100) / 5] = 2000 units

This indicates that ordering 2000 units at a time would minimize the total inventory cost. The reorder point calculation incorporates lead time demand. If lead time is 2 weeks and average weekly demand is 200 units, the ROP would be 400 units (2 weeks * 200 units/week). These calculations provide a starting point for optimizing inventory levels, which can be further refined through experience and more advanced techniques.

Implementing Inventory Tracking Systems

Effective inventory tracking is crucial for maintaining optimal stock levels, minimizing waste, and maximizing profitability. Choosing the right system depends on factors such as business size, budget, and the complexity of your inventory. This section will explore various inventory tracking methods and help you determine the best fit for your needs.

Implementing a robust inventory tracking system significantly improves operational efficiency and reduces the risk of stockouts or overstocking. By accurately monitoring inventory levels, businesses can make informed decisions about purchasing, production, and sales, ultimately leading to improved financial performance.

Examples of Inventory Tracking Software and Key Features

Several software solutions offer comprehensive inventory management capabilities. The choice depends on your specific needs and budget. Below are some examples with their key features.

Efficient Manage Inventory Like a Pro is crucial for any business, ensuring you always have the right products available to meet customer demand. However, simply having stock isn’t enough; you need to understand how to effectively move that inventory. This is where understanding the principles outlined in this helpful guide, Secrets to Increase Conversion Rates , becomes vital. By optimizing your sales strategy, you can significantly reduce excess stock and maximize profitability, further enhancing your inventory management prowess.

- Zoho Inventory: This cloud-based solution is suitable for small to medium-sized businesses.

- Features: Order management, automated purchase orders, barcode scanning, real-time inventory tracking, reporting and analytics, integration with other Zoho applications.

- Fishbowl Inventory: Designed for businesses using QuickBooks, Fishbowl provides robust inventory management capabilities integrated directly with accounting.

- Features: Manufacturing and assembly tracking, warehouse management, barcode scanning, detailed reporting, QuickBooks integration.

- InFlow Inventory: A user-friendly option for small businesses, InFlow offers a streamlined approach to inventory management.

- Features: Simple interface, barcode scanning, sales order processing, low stock alerts, reporting.

Manual vs. Automated Inventory Tracking Systems

The choice between manual and automated systems hinges on the scale and complexity of your inventory. While manual systems may suffice for very small businesses, automated systems offer significant advantages as inventory grows.

Efficient inventory management is crucial for any business aiming for success. Understanding your stock levels allows for precise forecasting and avoids costly overstocking. This accurate forecasting directly impacts your shipping needs, which is why understanding Shipping Strategies for Growth is so important. Ultimately, optimizing both inventory and shipping ensures smooth operations and maximized profitability, contributing to a well-managed business.

| System Type | Cost | Accuracy | Efficiency | Scalability |

|---|---|---|---|---|

| Manual | Low initial cost, high labor cost | Prone to human error; low accuracy | Inefficient, time-consuming | Limited; difficult to scale |

| Automated | Higher initial cost, lower labor cost | High accuracy due to automation | Highly efficient, real-time data | Easily scalable to accommodate growth |

Implementing Barcode or RFID Systems

Barcode and RFID systems provide highly accurate and efficient inventory tracking. Barcodes are relatively inexpensive and widely used, while RFID offers greater capabilities for tracking large volumes of items and their location within a warehouse.

Implementing a barcode system involves assigning unique barcodes to each item, using barcode scanners to track movement, and integrating the scanner data with your inventory management system. An RFID system utilizes radio-frequency identification tags attached to items, allowing for automated tracking without direct line-of-sight scanning. RFID offers advantages in speed and the ability to track multiple items simultaneously, making it ideal for high-volume environments. The choice between barcode and RFID depends on the specific needs of the business, considering factors such as budget, volume of items, and required tracking accuracy.

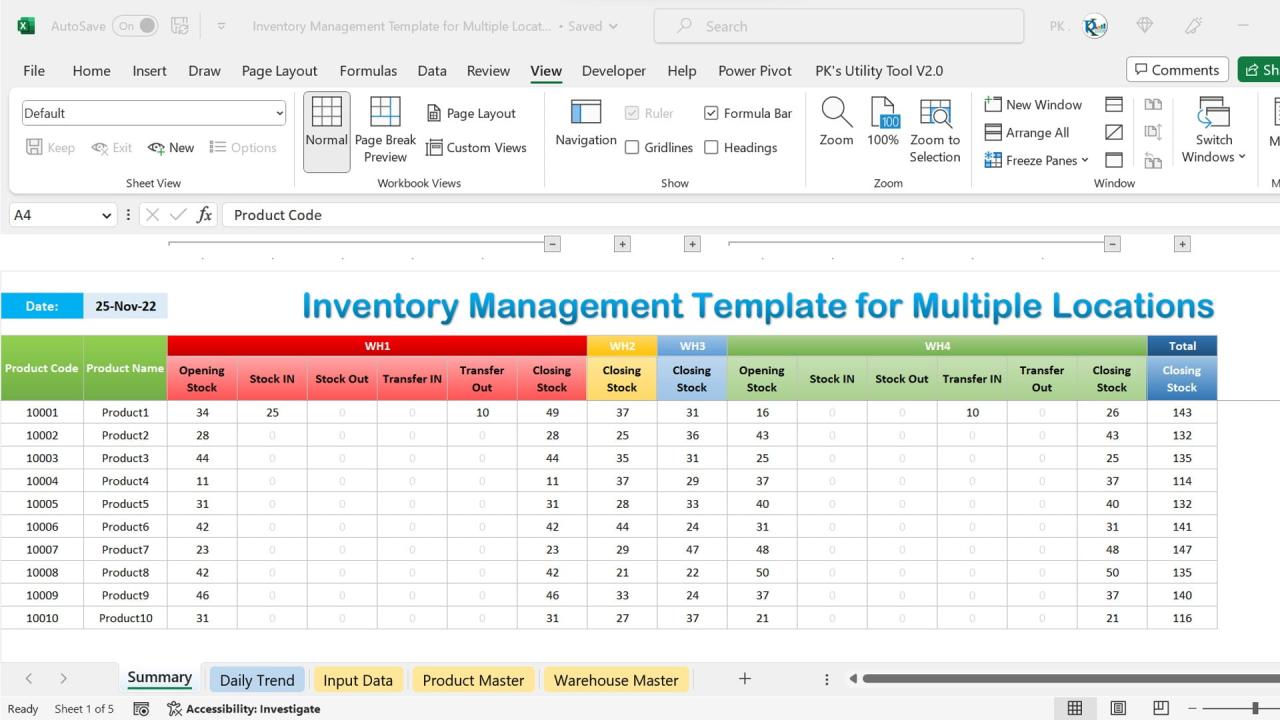

Managing Inventory Across Multiple Locations

Effectively Manage Inventory Like a Pro cross multiple locations presents unique challenges, demanding sophisticated strategies to ensure accuracy, efficiency, and profitability. This requires a robust system that can seamlessly integrate data from various points, providing a unified view of inventory levels and movement. Failing to do so can lead to stockouts, overstocking, increased costs, and ultimately, lost revenue.

Synchronizing Manage Inventory Like a Pro data across different warehouses or stores necessitates a centralized inventory management system. This system acts as a single source of truth, providing real-time visibility into inventory levels at each location. The system should automatically update inventory counts whenever a transaction occurs – whether it’s a sale, a shipment between warehouses, or a stock adjustment. This eliminates discrepancies and ensures everyone is working with the same information. Data synchronization can be achieved through various methods, including cloud-based software, dedicated inventory management systems, or even custom-built solutions, depending on the scale and complexity of the operation. For instance, a large retail chain might utilize a sophisticated Enterprise Resource Planning (ERP) system to manage its inventory across hundreds of stores, while a smaller business might find a simpler cloud-based solution sufficient.

Data Synchronization Methods

Several methods exist for synchronizing inventory data across multiple locations. These include real-time data feeds, scheduled updates, and manual reconciliation. Real-time data feeds provide the most up-to-date information, minimizing the risk of discrepancies. However, this approach requires a robust and reliable network infrastructure. Scheduled updates, on the other hand, are less demanding on the network but may introduce a slight delay in data accuracy. Manual reconciliation is generally the least efficient and most error-prone method and should be avoided whenever possible, except perhaps for very small operations. The choice of method depends on factors such as the size of the business, the number of locations, the complexity of the inventory, and the available technology.

Multi-Channel Inventory Management

Manage Inventory Like a Pro in a multi-channel environment, such as online and brick-and-mortar stores, requires a sophisticated approach that considers the unique characteristics of each channel. A centralized inventory management system is crucial for tracking inventory across all channels and ensuring accurate stock levels. This system should be able to handle different order fulfillment methods, such as direct-to-consumer shipping from a warehouse or in-store pickup. For example, a company selling products online and through physical stores needs a system that can seamlessly track inventory across both channels and allocate stock appropriately. If a customer orders a product online, the system should automatically deduct the item from the total inventory and update the stock levels across all locations. This prevents overselling and ensures accurate order fulfillment. Furthermore, effective demand forecasting, taking into account seasonal variations and promotional campaigns across both channels, is crucial for optimizing inventory levels and minimizing waste.

Real-Time Inventory Visibility Manage Inventory Like a Pro

Real-time inventory visibility is paramount for efficient inventory management across multiple locations. It allows businesses to make informed decisions about procurement, allocation, and order fulfillment, ultimately minimizing stockouts and overstocking. Achieving real-time visibility requires a combination of technology and processes. This includes using barcode or RFID scanning at every stage of the inventory lifecycle, implementing a robust inventory management system that updates inventory levels in real-time, and integrating data from different sources, such as point-of-sale (POS) systems, warehouse management systems (WMS), and e-commerce platforms. For instance, imagine a scenario where a retail chain experiences a sudden surge in demand for a particular product at one of its stores. With real-time inventory visibility, the company can quickly identify the shortage, transfer stock from another location, and prevent lost sales. The lack of real-time visibility could lead to lost sales and frustrated customers.

Reducing Inventory Waste and Losses

Inventory shrinkage, the difference between the recorded inventory and the actual physical inventory, significantly impacts profitability. Understanding its causes and implementing effective preventative measures is crucial for maintaining a healthy bottom line. This section explores common causes of inventory loss and Artikels strategies for minimizing waste and maximizing efficiency.

Minimizing inventory waste and losses requires a multi-pronged approach focusing on prevention, detection, and mitigation. Effective strategies involve implementing robust security measures, optimizing storage and handling, and proactively managing slow-moving or obsolete items. These strategies not only reduce financial losses but also improve operational efficiency and enhance overall inventory management.

Common Causes of Inventory Shrinkage

Inventory shrinkage stems from several sources, each requiring a specific approach for mitigation. Theft, both internal and external, accounts for a significant portion of losses. Damage, resulting from poor handling, inadequate storage, or natural deterioration, contributes substantially. Finally, obsolescence, where items become outdated or unsellable, leads to significant write-offs. Addressing these issues requires a combination of security measures, process improvements, and careful inventory planning.

Improving Storage and Handling Practices to Minimize Waste

Efficient storage and handling practices are fundamental to reducing inventory waste. Properly organized warehouses, with clear labeling and designated storage areas for different product types, minimize misplacement and damage. Implementing a first-in, first-out (FIFO) system ensures that older items are used before newer ones, reducing the risk of obsolescence. Investing in appropriate equipment, such as forklifts and pallet jacks, improves handling efficiency and minimizes the risk of damage during movement. Regular inspections of storage areas and equipment maintenance are crucial to identifying and addressing potential problems proactively. For example, a well-lit warehouse with clear aisle markings reduces the chance of accidental damage to goods. Implementing a system for regularly checking stock levels and promptly reporting any discrepancies helps identify issues early.

Managing Slow-Moving and Obsolete Inventory

Slow-moving and obsolete inventory ties up capital and occupies valuable storage space. Strategies for managing these items include implementing a robust inventory tracking system that identifies slow-moving items based on sales data and turnover rates. Analyzing sales trends helps predict future demand and prevent overstocking. Discounting or offering promotional pricing can help clear out slow-moving inventory. Donating or recycling obsolete items can reduce waste and potentially generate tax benefits. In some cases, it may be necessary to write off the value of obsolete inventory. For instance, a clothing retailer might heavily discount last season’s styles to make room for new stock, preventing the items from becoming completely obsolete and unsaleable. Alternatively, a technology company might recycle obsolete components, recovering some value while reducing environmental impact.

Analyzing Inventory Data for Improvement: Manage Inventory Like A Pro

Effective inventory management isn’t just about tracking items; it’s about using that data to make informed decisions that boost profitability and efficiency. Analyzing inventory data allows you to identify trends, pinpoint weaknesses, and optimize your processes for better results. By leveraging key performance indicators (KPIs) and interpreting inventory reports, businesses can proactively address issues and prevent potential losses.

Key Performance Indicators for Inventory Management

Understanding and monitoring key performance indicators (KPIs) is crucial for evaluating the health and efficiency of your inventory management system. These metrics provide quantifiable insights into various aspects of your inventory, enabling data-driven decision-making. Regularly tracking these KPIs allows for early identification of potential problems and facilitates timely interventions.

- Inventory Turnover Rate: This metric indicates how efficiently you’re selling your inventory. A higher turnover rate generally suggests strong sales and efficient inventory management. A low turnover rate might signal overstocking or slow-moving items.

- Gross Profit Margin: This shows the profitability of your inventory after accounting for the cost of goods sold. Analyzing this KPI helps determine the pricing strategy and identify items with higher profit margins.

- Inventory Holding Cost: This represents the expenses associated with storing and maintaining your inventory, including warehousing, insurance, and potential obsolescence costs. Tracking this KPI helps optimize storage strategies and minimize unnecessary expenses.

- Stockout Rate: This measures the frequency of stockouts, which can lead to lost sales and dissatisfied customers. A high stockout rate indicates a need for improved forecasting and inventory replenishment strategies.

- Order Fulfillment Rate: This metric indicates the percentage of orders fulfilled on time and in full. It’s a critical indicator of customer satisfaction and operational efficiency.

Interpreting Inventory Reports to Identify Areas for Improvement

Inventory reports provide a comprehensive overview of your inventory status, revealing valuable insights for improvement. Analyzing these reports requires a systematic approach, focusing on identifying trends and anomalies. For instance, consistently low turnover rates for specific products may indicate a need for price adjustments or promotional campaigns. Conversely, a high stockout rate for a particular item suggests the need for more accurate demand forecasting and improved replenishment processes. Regularly reviewing reports, comparing them against past performance, and identifying variances helps to pinpoint areas requiring attention. For example, a sudden spike in inventory holding costs could point to inefficient storage practices or an overstocked warehouse.

A System for Regularly Reviewing and Adjusting Inventory Policies

Establishing a structured system for reviewing and adjusting inventory policies based on data analysis is critical for continuous improvement. This involves setting regular review periods (e.g., monthly or quarterly), defining specific metrics to monitor, and establishing clear decision-making criteria. For example, if the inventory turnover rate consistently falls below a predetermined threshold, the system might automatically trigger a review of pricing strategies or demand forecasts. Similarly, a high stockout rate for a specific item might lead to adjustments in safety stock levels or supplier relationships. This proactive approach ensures that inventory policies are dynamically adjusted based on real-time data, leading to optimized inventory levels and improved operational efficiency. The process should also include documentation of changes made, the rationale behind those changes, and the subsequent impact on key performance indicators. This documentation creates a valuable historical record for future reference and continuous learning.

Technology’s Role in Manage Inventory Like a Pro

In today’s dynamic business environment, leveraging technology is no longer a luxury but a necessity for effective inventory management. Modern solutions offer unprecedented visibility, control, and efficiency, allowing businesses of all sizes to optimize their stock levels, reduce waste, and improve profitability. This section explores the transformative impact of technology on inventory management, focusing on cloud-based solutions, data analytics, and automation.

The integration of technology significantly enhances inventory management capabilities, streamlining processes and providing valuable insights that drive better decision-making. This leads to reduced operational costs, improved customer satisfaction through better order fulfillment, and a more competitive market position.

Cloud-Based Manage Inventory Like a Pro Solutions

Cloud-based inventory management systems offer several key advantages. These solutions eliminate the need for on-site servers and complex IT infrastructure, reducing upfront costs and ongoing maintenance. Data accessibility is improved, with authorized personnel able to access real-time inventory information from anywhere with an internet connection. This fosters better collaboration across teams and locations. Scalability is another major benefit; cloud-based systems can easily adapt to changing business needs, accommodating growth without significant IT investment. Furthermore, regular software updates and enhanced security features are typically included as part of the service, ensuring the system remains current and protected. For example, a small retail business using a cloud-based system can easily track inventory across multiple stores, automatically generating reports on sales trends and low-stock items, while a large manufacturing company can utilize the same technology to manage complex supply chains and optimize production scheduling.

Data Analytics and Machine Learning for Inventory Optimization

Data analytics and machine learning are revolutionizing inventory management by enabling businesses to move beyond simple reporting to predictive analysis. By analyzing historical sales data, seasonality, and other relevant factors, these technologies can forecast future demand with greater accuracy. This allows for more precise inventory planning, minimizing stockouts and reducing the risk of overstocking. Machine learning algorithms can also identify patterns and anomalies in data, flagging potential issues such as slow-moving inventory or potential supply chain disruptions. For instance, a clothing retailer might use machine learning to predict which styles will be most popular during the upcoming holiday season, allowing them to optimize their orders and avoid excess inventory. A food distributor could utilize data analytics to anticipate spikes in demand based on weather patterns or special events, ensuring sufficient stock is available to meet customer needs.

Automation for Improved Manage Inventory Like a ProAccuracy and Efficiency

Automation plays a crucial role in enhancing inventory accuracy and efficiency. Barcode scanners, RFID tags, and automated data entry systems significantly reduce manual data entry errors, a common source of inaccuracy in inventory management. Automated replenishment systems can automatically generate purchase orders when stock levels fall below predefined thresholds, eliminating the need for manual ordering and reducing the risk of stockouts. Warehouse automation, including automated guided vehicles (AGVs) and robotic picking systems, streamlines the movement of goods within the warehouse, improving efficiency and reducing labor costs. For example, a large distribution center might use AGVs to transport pallets of goods to designated locations, while a smaller warehouse might employ a robotic arm to pick and pack orders, increasing throughput and accuracy. These automation technologies significantly reduce the potential for human error and streamline inventory processes, leading to substantial improvements in accuracy and efficiency.

Building a Robust Manage Inventory Like a Pro Team

A well-structured and skilled inventory management team is crucial for the success of any business relying on efficient inventory control. A strong team ensures accurate tracking, minimizes waste, and optimizes stock levels, ultimately contributing to improved profitability and customer satisfaction. This section will Artikel the key components of building such a team.

Roles and Responsibilities within an Manage Inventory Like a Pro Team

An effective inventory management team typically includes individuals with diverse skills and responsibilities. Clear role definition prevents duplication of effort and ensures accountability. For example, a team might include a team lead or manager responsible for overall strategy and performance, inventory analysts who focus on data analysis and forecasting, warehouse staff responsible for physical inventory handling, and potentially specialists in inventory software or specific inventory management systems. Each role contributes to the overall efficiency and accuracy of the inventory management process. The responsibilities of each role should be clearly documented and regularly reviewed to ensure alignment with business objectives.

Training and Development for Inventory Staff

Investing in training and development is essential for maintaining a high-performing inventory management team. Regular training programs should cover areas such as inventory management software, best practices in warehousing and logistics, data analysis techniques, and effective communication skills. This training can include workshops, online courses, or on-the-job mentoring. Continuous learning ensures that staff are equipped with the latest knowledge and skills to handle evolving challenges and leverage new technologies within the field of inventory management. For instance, training on new warehouse management systems (WMS) is crucial when implementing such a system to ensure smooth transition and optimal utilization.

Fostering Collaboration and Communication within the Inventory Management Team

Effective communication and collaboration are vital for a cohesive and efficient inventory management team. Regular team meetings, open communication channels (such as instant messaging or project management software), and clear reporting structures facilitate information sharing and problem-solving. Establishing a culture of teamwork and mutual respect is crucial for fostering a positive and productive work environment. Implementing tools like shared spreadsheets or inventory management dashboards can enhance transparency and facilitate collaborative decision-making. For example, a daily stand-up meeting can help address immediate challenges, while weekly meetings could focus on longer-term strategies and performance review.

By implementing the strategies and techniques Artikeld in this guide, you can confidently navigate the complexities of inventory management. From understanding fundamental principles to leveraging advanced technologies, you’ll be well-equipped to optimize your processes, minimize waste, and maximize profitability. Remember, consistent monitoring, data analysis, and team collaboration are key to long-term success. Embrace a proactive approach, and watch your inventory management evolve from a reactive function to a strategic asset driving growth and efficiency.